Flat plate collectors are an important technology in the field of renewable energy. They are used to harness solar radiation and convert it into thermal energy, which can be used for various applications, such as heating water and space in residential and commercial buildings. Understanding the science behind flat plate collectors and how they work is crucial in the development of sustainable energy systems.

Flat plate collectors consist of several components, including the absorber plate, glazing, insulation, and fluid circulation system. These components work together to collect solar radiation, convert it into thermal energy, and transfer it to a fluid that can be used for hot water and space heating. The technology is cost-effective, environmentally friendly, and requires minimal maintenance, making it a popular choice for many applications.

What is a Flat Plate Collector?

A flat plate collector is a device used for capturing solar radiation and converting it into thermal energy. It is commonly used for heating water and space in residential and commercial buildings. The collector consists of a flat, rectangular box with a dark-colored absorber plate inside. The plate is covered with a glazing material, such as glass or plastic, which allows sunlight to pass through while reducing heat loss.

Underneath the absorber plate, there is a fluid circulation system consisting of pipes or tubes. The pipes or tubes are filled with a heat transfer fluid, such as water or antifreeze, which absorbs the heat from the absorber plate and carries it away to a storage tank or heat exchanger. The storage tank or heat exchanger can then distribute the thermal energy for various applications, such as heating water or space.

Flat plate collectors are highly efficient at converting solar radiation into thermal energy. They can be used in a variety of climates and can even work in cloudy weather conditions.

How Do Flat Plate Collectors Work?

Flat plate collectors work by using a series of components to capture solar radiation and convert it into thermal energy. The basic components of a flat plate collector include an absorber plate, glazing, insulation, and a fluid circulation system.

Point 1

The absorber plate absorbs solar radiation and converts it into thermal energy. The absorber plate is typically made of dark, heat-absorbing material, such as copper or aluminum. The plate is designed to absorb as much solar radiation as possible while minimizing reflection.

Point 2

The glazing material covers the absorber plate to reduce heat loss and protect the absorber plate from the elements. The glazing material is typically made of glass or plastic and is designed to allow sunlight to pass through while minimizing heat loss.

The insulation material is placed around the sides and back of the flat plate collector to reduce heat loss and increase efficiency. The insulation material is typically made of foam or fiberglass and is designed to prevent heat from escaping through the sides and back of the collector.

Point 3

The fluid circulation system circulates a heat transfer fluid through the pipes or tubes beneath the absorber plate. As the heat transfer fluid passes beneath the absorber plate, it absorbs the thermal energy and carries it away to a storage tank or heat exchanger. The storage tank or heat exchanger can then distribute the thermal energy for various applications, such as heating water or space.

Components of a Flat Plate Collector

Flat plate collectors consist of several components that work together to convert solar radiation into thermal energy. These components include:

Absorber Plate: The absorber plate is the most important component of the flat plate collector. It is usually made of copper or aluminum and is coated with a selective coating that absorbs solar radiation and minimizes heat loss.

Glazing: The glazing is a transparent cover that protects the absorber plate from the environment and reduces heat loss. The glazing is usually made of tempered glass or plastic.

Insulation: Insulation is a layer of material that surrounds the collector box and reduces heat loss.

Fluid Circulation System: The fluid circulation system consists of pipes that carry the heated fluid from the absorber plate to the storage tank.

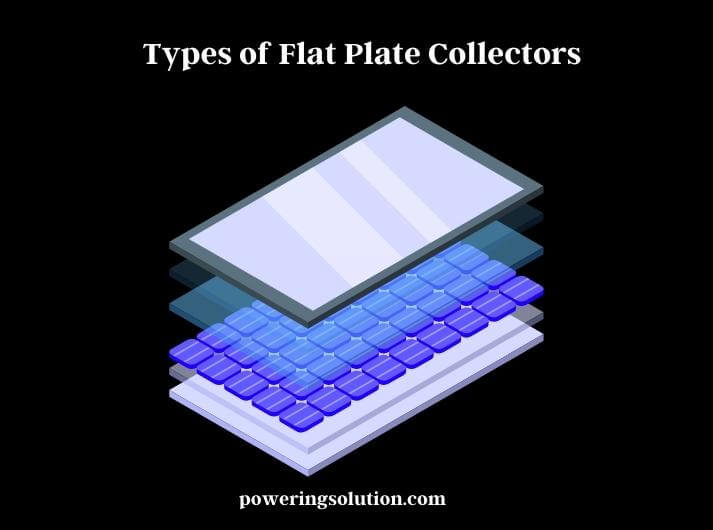

Types of Flat Plate Collectors

There are two main types of flat plate collectors: glazed and unglazed.

Glazed flat plate collectors are the most common type of flat plate collector. They consist of an absorber plate covered with a glazing material, such as glass or plastic. The glazing material reduces heat loss and protects the absorber plate from the elements. Glazed flat plate collectors are typically used for heating water and space in residential and commercial buildings.

Unglazed flat plate collectors do not have a glazing material and are often used for applications that do not require high temperatures, such as heating swimming pools. Unglazed flat plate collectors are typically less expensive than glazed collectors and can be used in a variety of climates.

There are also variations of flat plate collectors that are designed for specific applications. For example, some flat plate collectors are designed for use in cold climates and have insulation material to prevent heat loss. Other flat plate collectors are designed for use in hot climates and have reflective surfaces to reduce heat absorption.

The type of flat plate collector chosen for a particular application will depend on factors such as climate, temperature requirements, and cost. Glazed flat plate collectors are the most common type and are suitable for many applications, while unglazed flat plate collectors are more cost-effective and suitable for applications that do not require high temperatures.

Advantages of Using Flat Plate Collectors

There are several advantages to using flat plate collectors as a source of renewable energy:

- Cost-effective: Flat plate collectors are relatively inexpensive to manufacture and install, making them a cost-effective source of renewable energy.

- Low maintenance: Flat plate collectors require minimal maintenance and can last for up to 25 years or more with proper care.

- Environmentally friendly: Flat plate collectors do not produce any greenhouse gas emissions or air pollution, making them an environmentally friendly source of renewable energy.

- Reliable: Flat plate collectors are a reliable source of renewable energy, as they can operate in a variety of climates and weather conditions.

- Versatile: Flat plate collectors can be used for a variety of applications, such as heating water or space in residential and commercial buildings, heating swimming pools, and powering industrial processes.

- Energy independence: By using flat plate collectors as a source of renewable energy, individuals and businesses can reduce their dependence on fossil fuels and achieve greater energy independence.

Disadvantages of Using Flat Plate Collectors

While there are several advantages to using flat plate collectors, there are also some disadvantages to consider:

- Limited efficiency: Flat plate collectors have limited efficiency in converting solar energy into heat, meaning they may not be suitable for applications requiring high temperatures or large amounts of energy.

- Dependent on the weather: Flat plate collectors rely on sunlight to generate energy, which means they may not be as effective in areas with limited sunlight or during periods of cloudy weather.

- Large space requirement: Flat plate collectors require a significant amount of space to be installed, making them unsuitable for some residential or commercial properties with limited space.

- Initial cost: While flat plate collectors are cost-effective in the long run, the initial cost of installation may be high for some individuals or businesses.

- Maintenance and durability: While flat plate collectors require minimal maintenance, they do require periodic cleaning and inspection to ensure proper function. Additionally, the absorber plate and glazing material can degrade over time, requiring replacement or repair.

Despite these drawbacks, flat plate collectors remain a viable source of renewable energy for many applications.

Maintenance of Flat Plate Collectors

Flat plate collectors require minimal maintenance to function properly and efficiently. However, some periodic maintenance is necessary to ensure the longevity and optimal performance of the system. Here are some tips for maintaining flat plate collectors:

| Regular cleaning | The surface of the collector should be kept clean and free from dust, dirt, and debris to ensure maximum solar energy absorption. The recommended cleaning frequency is once or twice a year, depending on the location and weather conditions. |

| Inspection | Regular inspection of the collector, absorber plate, and glazing material is necessary to detect any cracks, leaks, or damage that may affect the system’s performance. |

| Sealing | The seals around the glazing material and other components should be inspected and replaced if necessary to prevent leaks and ensure proper insulation. |

| Antifreeze replacement | If the flat plate collector is used to heat a liquid, the antifreeze should be checked and replaced periodically to prevent freezing and damage to the system. |

| Professional servicing | For complex systems, professional servicing may be necessary to ensure optimal performance and safety. A certified technician can perform routine maintenance, inspection, and repair as needed. |

Applications of Flat Plate Collectors

Flat plate collectors have a wide range of applications in both residential and commercial settings. Some common applications include:

- Domestic hot water: Flat plate collectors can be used to heat water for domestic use, such as showers and washing machines. They are particularly useful in areas with high solar radiation and high demand for hot water.

- Space heating: Flat plate collectors can be used to heat the air in a room or building, providing a cost-effective and energy-efficient alternative to traditional heating systems.

- Swimming pool heating: Flat plate collectors can be used to heat swimming pools, extending the swimming season and reducing the energy costs associated with pool heating.

- Industrial process heating: Flat plate collectors can be used in industrial settings to heat water or other fluids for various manufacturing processes.

- Agricultural applications: Flat plate collectors can be used to heat water for agricultural purposes, such as crop irrigation and livestock watering.

- Solar cooling: Flat plate collectors can also be used to drive absorption chillers to provide cooling in buildings, particularly in areas with high solar radiation and cooling demand.

Final Verdict

Flat plate collectors are an excellent source of renewable energy for both residential and commercial applications. They work by absorbing solar energy and converting it into heat, which can be used for a variety of purposes, such as heating water, space heating, and pool heating.

Flat plate collectors have many advantages over traditional heating systems, including lower energy costs, reduced environmental impact, and long lifespan. However, they also have some disadvantages, such as lower efficiency in cold weather and high initial installation costs. To ensure optimal performance, flat plate collectors require regular maintenance and periodic professional servicing. Despite these considerations, flat plate collectors remain a viable and attractive option for those looking to reduce their energy costs and environmental impact.